Okuma America’s ‘Make the Leap’ technology showcase highlights advanced CNC manufacturing technologies.

Charlotte, North Carolina – Okuma America Corp. hosted more than 500 customers, partners and distributors at its 2014 Technology Showcase event on Dec. 9-10, 2014 in Charlotte North Carolina. This two-day event featured a wide array of learning opportunities for attendees featuring hands-on demonstrations, App Store and machine demos, a facility tour highlighting titanium machining at the new Aerospace Center for Excellence, and a behind-the-scenes look at Okuma’s electrical and mechanical repair operations.The theme of this year’s event, “Make the Leap,” included demonstrations of simple technology upgrades that enable users to quickly jump ahead of their competition and enhance the productivity of their CNC machines and operators, thus improving overall profitability. For each technology shown, a side-by-side demonstration of basic vs. advanced machine functionalities and the benefits that can be gained by leaping into higher technology were featured.

The demonstrations were relevant to a wide variety of industries, including aerospace, automotive, construction/farming (heavy equipment), die/mold, firearms/munitions, medical, oil/energy, and general job shops.

Members of Partners in THINC demonstrated how peripheral equipment such as tooling, gaging, workholding, and automation can be integrated with Okuma technology to improve productivity.

“Make the Leap” CNC machine demonstrations

Each side-by-side demonstration gave attendees tips on how they can use advanced CNC machine technology to create a competitive advantage in their marketplace. Examples included:

- 2-axis vs. 4-axis Lathes – side-by-side cutting demonstration of Okuma’s LB EX-II and LU EX lathes show how a 4-axis CNC lathe can easily combine operations to reduce cutting time, improve quality, enhance flexibility and increase throughput

- VMC vs. HMC – how a horizontal machining center increases overall throughput, improves quality and reduces labor, WIP and floor space, all without significantly increasing capital budget

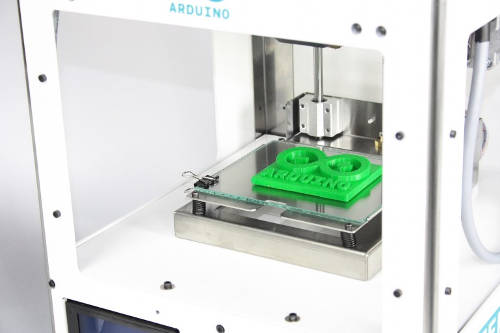

- The Okuma App Store – Machine tool apps can significantly impact the effectiveness and efficiency of machine tools – yes, there IS an app for that

- MA-12500H horizontal machining center – debuted at IMTS 2014

- MU-10000H 5-axis horizontal machining center – Okuma’s largest 5-axis machine

- MULTUS U Series – Okuma’s newest multitasking CNC machines

- Okuma’s “Affordable Excellence” products – GENOS CNC lathes and machining centers, LB3000 EX-II and MB-5000H machining centers – functionality at an affordable price